ultrasonic hardness testing principles|equotip 550 hardness tester : private label Basic Principles of Ultrasonic Testing. Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used .

Resultado da Launch your iGaming business with SOFTSWISS. We offer the best iGaming software and customer service. SOFTSWISS is a gambling software .

{plog:ftitle_list}

webHyundai HB20 1.6 Premium 2015. R$ 52.000. Preto. 60.431 km. Manual. Ver todas as ofertas. publicidade. Veja o preço FIPE e KBB do carro Hyundai HB20 1.6 Premium 2015. Confira também o preço .

Ultrasonic testing (UT) can generate ultrasonic waves penetrating deep (several meters) inside the specimen to diagnose pores, including sizes and shapes, in a non . Ultrasonic Hardness Testers can provide fast, reliable test results and the test can be automated. With a Small indentation size/depth, the .

In ultrasonic testing, an ultrasound transducer connected to a diagnostic machine is passed over the object being inspected. The transducer is typically separated from the test object by a couplant such as a gel, oil or water, as in immersion testing. However, when ultrasonic testing is conducted with an Electromagnetic Acoustic Transducer (EMAT) the use of couplant is not required.This guide delves into the fundamental aspects of ultrasonic testing, exploring its principles, the tools inspectors use to do it, different types of UT methods, and the scenarios in which UT is most beneficial. This chapter gives an overview of the different ultrasonic techniques commonly used today to characterize materials properties of solids (metal alloys). Ultrasonic testing is one of .Basic Principles of Ultrasonic Testing. Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used .

The document is a hand book for Non Destructive Testing Engineers to perform Ultrasonic Testing , explains the applicable type of defects, basics of Ultrasonic Testing, Applicable . 1. Equipment Configuration: The essential apparatus for Ultrasonic Testing encompasses three primary components: a transducer (also referred to as a probe), a couplant, and a display unit. The Ultrasonic Transducer, a . Ultrasonic testing parameters are significantly influenced by variations in microstructural or mechanical properties of materials. Some of the important material properties that have been correlated with ultrasonic testing parameters are grain size, hardness, fracture toughness, yield strength, texture, residual stress and fatigue .

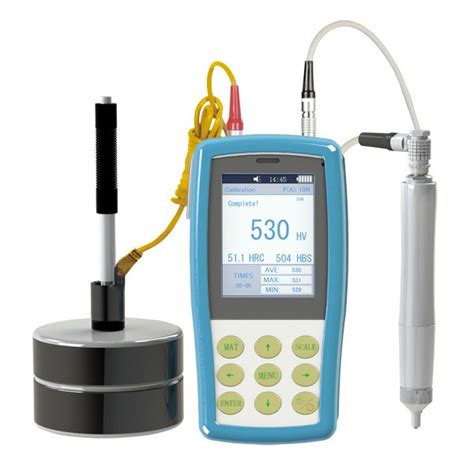

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness .Hardness Testers. alphaDUR mini II; Proceq Equotip 550; Coating Inspection Equipment. PCWI DC30; Tinker & Rasor AP/W; Fischer FMP 30 Deltascope; PosiTector 6000; . Principles of Ultrasonic Testing. The basic principle of . Hardness testing is absolutely critical in many industries and phases of manufacturing. Detecting defects during this process can save thousands of dollars and a lot of headaches later due to product or structural failure. Yet, traditional hardness testing is destructive to the test sample. In many cases, this is not what you want. Instead, you want to .Hardness testing using the MIC 20 in combination with the test support MIC 227 and a UCI probe in the heat-affected zone (HAZ) of a weld. Fig. 2: Hardness testing with a rebound hardness tester (DynaMIC) on the drive wheel of a large hydraulic excavator. Fig. 3: Hardness testing using the DynaPOCKET on the chain of an open-pit mining excavator .

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .PORTABLE HARDNESS TESTING – PRINCIPLES AND APPLICATIONS Dr. Stefan Frank Agfa NDT GmbH, Robert-Bosch-Str. 3, D-50354 Huerth, Germany . to the size of the test indentation in the material generated by a certain test load also arises in Vickers hardness testing according to the UCI (Ultrasonic Contact Impedance) method. However, the diagonals .

Hardness Testing: Principles and Applications is an in-depth study of one of the most fundamental properties of materials and the tools and techniques that. . photothermal, and ultrasonic sensing, and indentation measurement techniques. The chapters also include application examples as well as guidelines and recommendations for selecting and .4.3 The UCI hardness test may be used on large or small components at various locations. It can be used to make hardness measurements on positions difficult to access, such as tooth flanks or roots of gears. A. GENERAL DESCRIPTION OF INSTRUMENTS AND TEST PROCEDURE FOR UCI HARDNESS TESTING 5. Apparatus 5.1 Instruments used for UCI hardness . The residual indentation size of the indenter can be measured using optical measurement methods. Among the standardized optical hardness testing methods are the Brinell hardness test (ISO 6506, ASTM E10), the Knoop hardness test (ISO 4545, ASTM E92, ASTM E384), and the Vickers hardness test (ISO 6507, ASTM E92, ASTM E384). Brinell . Ultrasonic testing uses sound waves to non-destructively inspect a component for flaws. Introduction. Ultrasonic testing is a non-destructive testing technique because the workpieces or components to be tested are not damaged during the test. If there are no complaints after the test, the component can continue to be used.

Hardness Testing Principles and Applications B-ASM-038. This publication provides, based on the state of standardization, an overview of the hardness testing of metals, plastics, rubber and other materials. It reports on technical developments such as the introduction of image processing in the Brinell and Vickers method, the adaptation of .Basic Principles of Ultrasonic Testing. Ultrasonic Testing (UT) uses high frequency sound energy to conduct examinations and make measurements. Ultrasonic inspection can be used for flaw detection/evaluation, dimensional measurements, material characterization, and more. To illustrate the general inspection principle, a typical pulse/echo .If a testing machine is also to be used for other methods of hardness testing, it shall be verified independently for each method. ISO 6507-2:2018 is also applicable to portable hardness testing machines but not applicable to hardness testing machines based on different measurement principles, e.g. ultrasonic impedance method.

validation of hardness tester ppt

UCI method for the hardness testing: Ultrasonic Hardness Tester's Motorized Probe: 0.3/0.5/0.8/1kgf. The UCI hardness measuring method complies to ASTM A1038. The ultrasonic contact impedance (UCI) probe is purposed to be .

ultrasonic hardness tester

The capability of ultrasonic torsion equipment to fatigue materials was demonstrated testing plain tube specimens of commercially produced 99% stabilized zirconia [11].The electronic equipment used to drive and control the ultrasonic torsion experiments was the same as that used in tension–compression investigations, whereas all mechanical .

In this article, we will delve into the principles and applications of the Vickers hardness testing method. Principles of Vickers Hardness Testing: The Vickers hardness test is based on the principle of indentation hardness, .Phased Array Ultrasonic Testing (PAUT) is a powerful and versatile non-destructive testing (NDT) technique widely used in various industries to inspect and evaluate the integrity of materials, welds, and components. It relies on the principles of ultrasonic sound waves to detect and characterize defects or anomalies within a test object. Results show that combining ultrasonic pulse velocity and Leeb hardness is an effective way to improve UCS estimations through portable and non-destructive techniques in non-porous . based on pulsed electromagnetic principles, with good results for sub-surface inspection . One of the advantages of the Leeb rebound hardness test, which is .

validation of hardness tester slideshare

Mobile hardness testing is on the advance: In these times of cost pressures and higher quality require- . one operating on the UCI Ultrasonic Contact Impedance principle (MIC 10) and the other on the rebound principle (DynaMIC and DynaPOCKET). This paper explains the basic principles of both test methods and compares, using examples from the . During the decades, various destructive and non-destructive hardness test methods have been developed. The non-destructive methods are portable and can be used on materials at the service, but a widely accepted non-destructive hardness test method, the ultrasonic contact impedance technique, is limited to measure the surface hardness.Ultrasonic testing is a non-destructive testing method that uses high-frequency sound waves to detect flaws in materials and ensure their integrity.Ultrasonic Testing (UT) is a widely used non-destructive testing method that utilizes high-frequency sound waves to detect flaws, defects, and irregularities. . Understanding the principles, benefits, and limitations of Ultrasonic Testing is essential for professionals in fields where materials’ integrity is of utmost importance.

It is equipped with two test systems: one for roll hardness measurement; The other is used for standard hardness testing. Principles of Digital Hardness Testing. Digital hardness testing is based on the principle of indentation, where a controlled force is applied to the surface of the material using a hardened indenter.The UCI Hardness Tester TCM-U3 operates according to the Ultrasonic Contact Impedance (UCI) method of hardness testing, and is standardized according to ASTM A 1038. The basic operating principle is that hardness is measured by detecting the frequency shift of a longitudinal oscillating rod fused to a Vickers diamond indenter.United States 1 S x̄ 2 x ref x ref DU (2) Distributed by Clarivate Analytics (US) LLC, www.techstreet.com. 3.1.3 UCI hardness test—a hardness testing method using a calibrated instrument by pressing a resonating rod with a defined indenter, for example, a Vickers diamond, with a fixed force against the surface of the part to be tested.Ultrasonic / UCI Hardness Tester PCE-3000ULS . The uci hardness tester can be used to quickly check the hardness of components even when installed. . The universal uci hardness tester enables express hardness testing of carbon and structural steels, welds, electroplated coatings, overlays, heat resistant, corrosion resistant and stainless .

ultrasonic contact impedance hardness tester

Collaborate for free with online versions of Microsoft Word, PowerPoint, Excel, and OneNote. Save documents, workbooks, and presentations online, in OneDrive. Share .

ultrasonic hardness testing principles|equotip 550 hardness tester